Waterflooding 101

Unconventional wells have dominated the oil industry recently, pushing traditional forms of development, like conventional waterfloods, out of the spotlight. Waterfloods have the ability to stabilize a field’s decline rate to 5% annually. They can give a company a steady, predictable base production. This article covers the basic concepts of waterflooding that I have learned while working waterflood projects over the years. I sympathize with people that lose interest when venturing too deep in the technical weeds, so I will try to keep this a simple and practical overview of the basic concepts of waterflooding.

What is waterflooding? Waterflooding is a type of secondary recovery, or enhanced oil recovery, where water is pumped down an “injector” well that offsets “producing” wells; the water sweeps oil from the injector to the producers. Think of a puddle on a table. If you and your friends stick straws into the puddle, you can move the liquid around by blowing or sucking on the straws. Injectors blow water into the reservoir; producers suck oil, gas, and water out. A waterflood works by using injectors to create flood fronts that trap and corral oil to producers for collection.

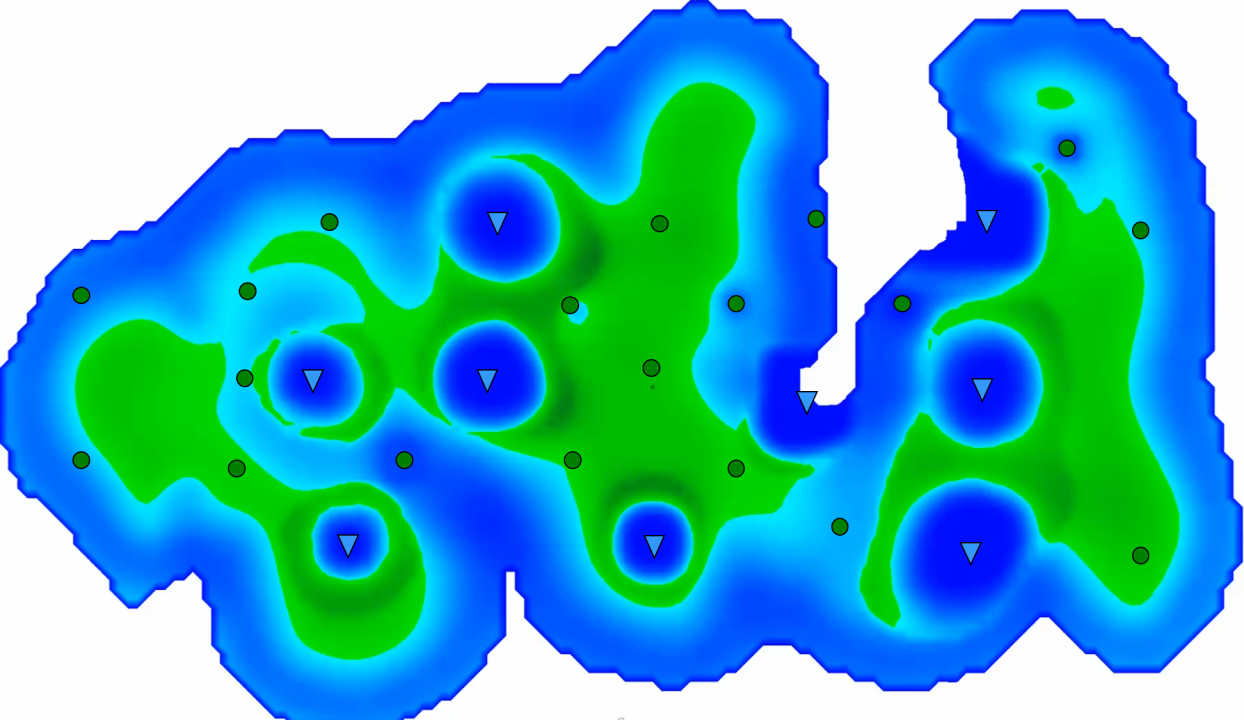

Waterflood patterns are standardized placements of injectors and producers that have historically proven to be efficient at displacing oil. Patterns create pressure boundaries within the reservoir that help direct flow. A uniform pattern creates a network of pressure boundaries so that water can efficiently sweep an area. Irregular, uniquely shaped, patterns will have the same forces act upon them, but may result in lower swept efficiencies. The most commonly used patterns are inverse 9-spot, 5-spot, line drive and peripheral; all but peripheral are shown in Figure 1.

In my experience, peripheral floods only work in models, specifically when the edge of a model acts as a boundary to redirect the flow of injected water back up the structure. This hard boundary does not exist in the physical world, instead an aquifer is usually present. Water follows the path of least resistance and it is easier for water to flow through water, than to flow through oil. I know of numerous peripheral floods that have pumped millions of barrels of water into the aquifer while producers on top of the structure see no pressure support. When standard waterflood patterns were created on top of the structure, the field’s production rate increased almost immediately.

Understanding the pressure boundaries created by patterns and how they influence flow is important for optimizing a waterflood. Returning to the puddle example, as you blow into an injector the force of your airstream becomes weaker as you run out of breath. If your friend took a bigger breath than you, they can maintain a stronger airstream longer. The stronger airstream will push the liquid towards the weaker airstream; this happens in the reservoir as well. Over time pressure boundaries between injectors will move based on the volume being injected and how pressure builds up in the reservoir. Streamline models are great for visualizing these pressure boundaries and predicting the flow paths of fluids in the reservoir.

Patterns have a strong influence on flow in your reservoir, but before establishing your pattern you need to understand what else can affect the flow. It is generally assumed that water injected into a well expands outwards into the reservoir in a circle (radial flow). The circle becomes distorted when it is influenced by pressure highs or lows (injectors and producers), flow barriers (faults), preferential flow (e.g. permeability anisotropy, hydraulic fracture orientation, etc) and/or reservoir properties (e.g. permeability, porosity, relative permeability, etc). Geology and physics play key roles in understanding your reservoir and how fluids flow within it.

Egypt has many fields containing “dead oil,” meaning there is little gas saturated in the oil. Once production has drawn down (reduced) the reservoir pressure, you lose the energy needed to get the oil out of the ground, i.e. the oil stops flowing. Waterflooding is an effective drive mechanism in these cases as it introduces energy into the system by increasing pressure at injectors. In nature, physics indicates that things will take the path of least resistance; this includes fluids in a reservoir which flow from high to low pressure. For this reason, it is important to minimize the producers’ bottom hole flowing pressure. This maintains maximum drawdown at the producer, attracting fluids in the reservoir.

“Live oil” areas, like the Midland Basin Platform, have a principal threshold that determines the efficiency of a waterflood, the bubble point. When the reservoir pressure falls below the bubble point, gas starts to come out of solution downhole. The gas is freed of its restraining bond to oil and flows rapidly to producers. Saturated gas is what keeps the oil “light;” as gas comes out of solution the oil becomes “heavy” and loses mobility. Once produced, the gas is removed from the reservoir system and there is no way to get it back in solution. Raising the reservoir pressure above bubble point will prevent additional gas from coming out of solution, but it cannot restore the oil’s mobility.

The relation between oil and water mobility determines the type of displacement. If your oil’s mobility is equivalent or better than the water being injected, then you will see piston-like displacement. If the oil is less mobile than the water pushing it, then you get a fingering effect. Instead of a block of water pushing a block of oil (piston-like), the water worms through the oil, creating tendrils of water similar to the fingers on your hand (fingering). Portions of the mobile oil are swept along with the water as it cycles between injectors and producers. Getting the remaining oil out is just a matter of time and money as the water is cycled through the reservoir. Many waterfloods do not begin until after a field falls below the bubble point, the downside of this is the loss of efficiency and increased cost to recover the oil.

When contemplating the reservoir in three dimensions, geology has a greater impact on understanding flow dynamics. If injecting into a zone with multiple layers (stratified reservoir), the water will travel at different rates in each layer. Permeability, porosity, saturation, pressure and flow barriers all influence flow. “Fast zones” refer to layers in a stratified reservoir with better reservoir properties, allowing fluid to travel rapidly between injector and producer. Water breaks through to a producer quicker when exposed to a fast zone; seeing water at a producer does not mean you have swept all the oil between the injector and producer, see Figure 3.

Flow barriers can come in various forms, the most common are faults. In the Western Desert of Egypt, most fields consist of faults completing a structural trap where oil collects. Families of faults make complex fields, compartmentalizing areas and creating multiple flow barriers. Knowing where these faults are located and whether they are sealing or leaking highly impacts a field’s development plan. Sealing faults can be used to contain and/or control flow paths. Leaking faults are like injecting through a filter, some pressure and volume will leak through but a large volume will form a bank along the fault. If a flow barrier divides two planned wells, their locations will need to be adjusted or additional wells will be needed to sweep the area.

The basic concepts of waterflooding discussed here include patterns, pressure boundaries, drive mechanics, solution gas, bubble point, mobility, fast zones, and faults. This barely scratches the surface of waterflooding topics, but now you have a foundation to start building on.

Written by Vanessa G Neal

Originally Published on LinkedIn February 12, 2020